Industrial power transmission components play a vital role in the operation of various industrial machinery and are used as an intermediary for transferring mechanical energy from one part to another in a variety of manufacturing and industrial processes. These components include a variety of systems such as gearboxes, gears, and belts that are used in large industries such as automotive, power generation, and machinery manufacturing.

In the midst of processes related to the purchase and sale of industrial equipment, the correct selection of these components is of particular importance, because the quality and accuracy of their performance directly affect the overall efficiency of production lines. Therefore, familiarity with the performance and types of these components is essential for industrial activists and engineers in the field of construction and production.

What is power transmission in industry?

Industrial power transmission components are among the most important components used in the power transmission process in industrial machinery and equipment. This process helps transfer the energy generated by the engine or power source to other moving components so that the device can function effectively. In various industries, this transmission can be done through mechanisms such as gears, belts or couplings. These systems must be designed in such a way that, in addition to transmitting mechanical power, they also control speed, torque and direction of movement.

In fact, without these systems, it would not be possible to optimally operate industrial engines and many machines would fail. Given the key role of this process, it is very important for engineers and production managers to accurately understand the function and structure of these components, especially when maintaining or upgrading machinery.

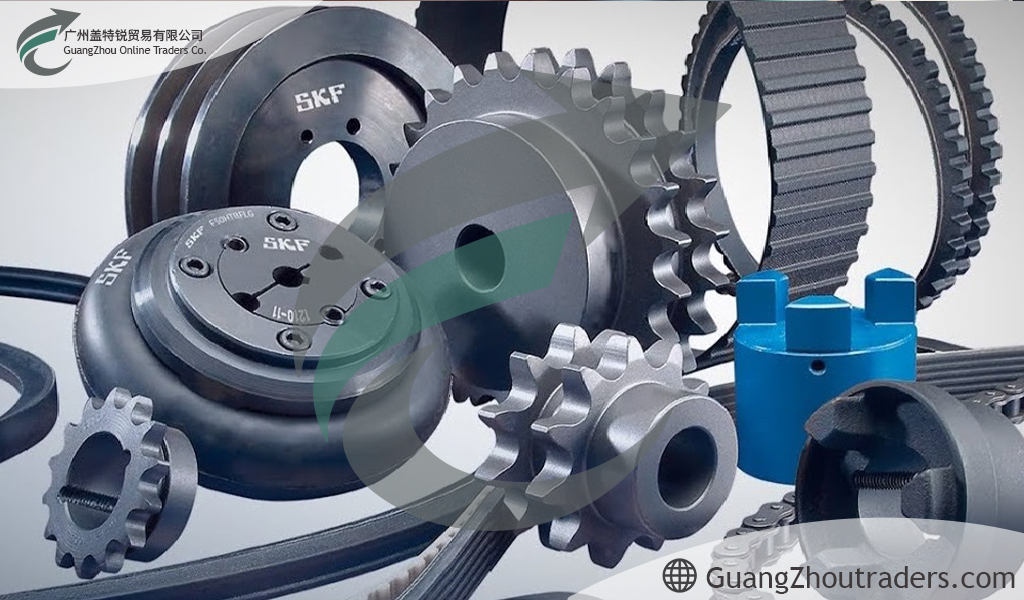

Types of Industrial Power Transmission Components

Industrial power transmission components play a fundamental role in the proper functioning of industrial machinery, and without these components, power transmission from the production source to the operational parts would not be possible. Each of these components has specific characteristics that make them suitable for a specific type of application.

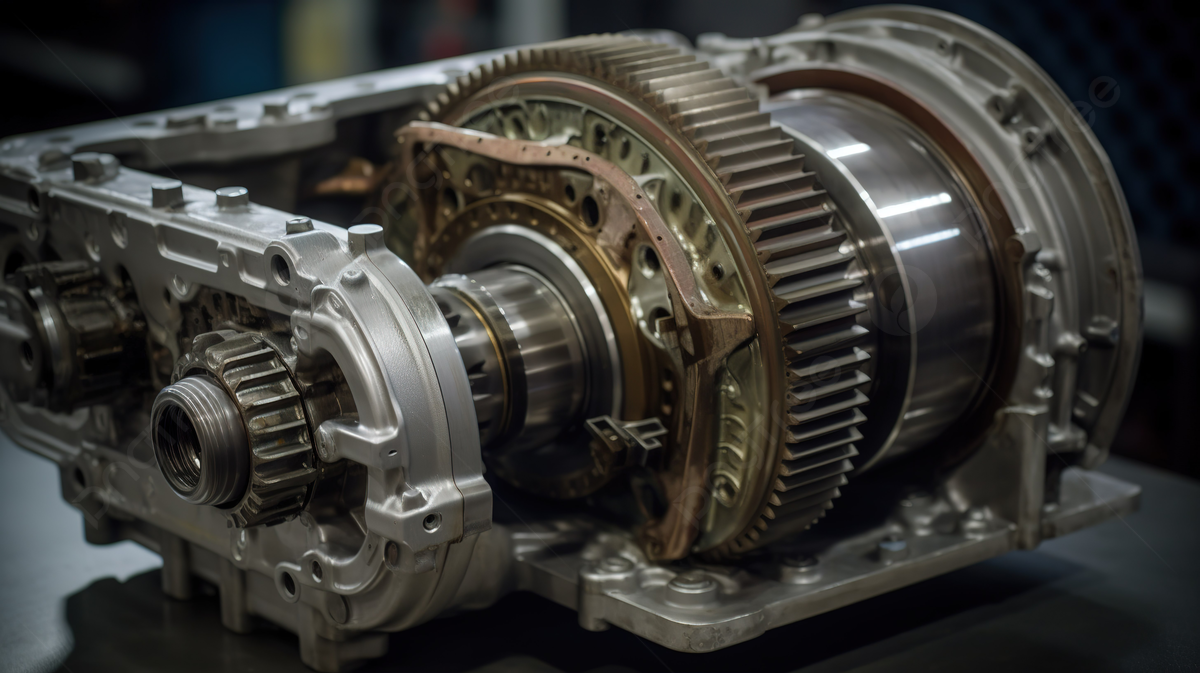

Gearboxes

Gearboxes are one of the most widely used power transmission components in industry, and their main function is to regulate and change the speed and torque transmitted. They provide mechanical energy in a desirable form for the operation of machinery by reducing or increasing the engine speed. Depending on the internal structure, various types of gearboxes are used in industry, such as worm gearboxes for low-noise speed reduction, helical gearboxes for high speeds, and solar or cyclo models for combining high precision and power.

Gears

Gears are one of the oldest power transmission methods used in mechanical systems to transmit power between two closely spaced axes. These components are usually used in machines that need to change direction or increase precision in movement. There are different types of gears, the most common of which include spur gears for direct power transmission, helical gears for angular speed reduction, and compound gears for better speed and torque control.

Belts

Belts are used as a flexible means of transmitting power between widely spaced shafts. They are used in light and heavy industries to transmit power from the engine to other system components such as fans, conveyors, or compressors. The advantages of belts include low cost, easy installation, and quiet operation. Types of belts include round belts for high-speed applications, timing belts for precise and coordinated movements, and V-belts for high-power power transmission.

Chains

Chains are used as one of the industrial power transmission components in the transmission of power between shafts that are further apart and are subjected to high mechanical pressures. These components are usually used in heavy machinery, engines or devices that have high loads. Common types of chains include roller chains, which are suitable for transmitting power in harsh conditions, and timing chains, which are used to precisely coordinate the movement of components.

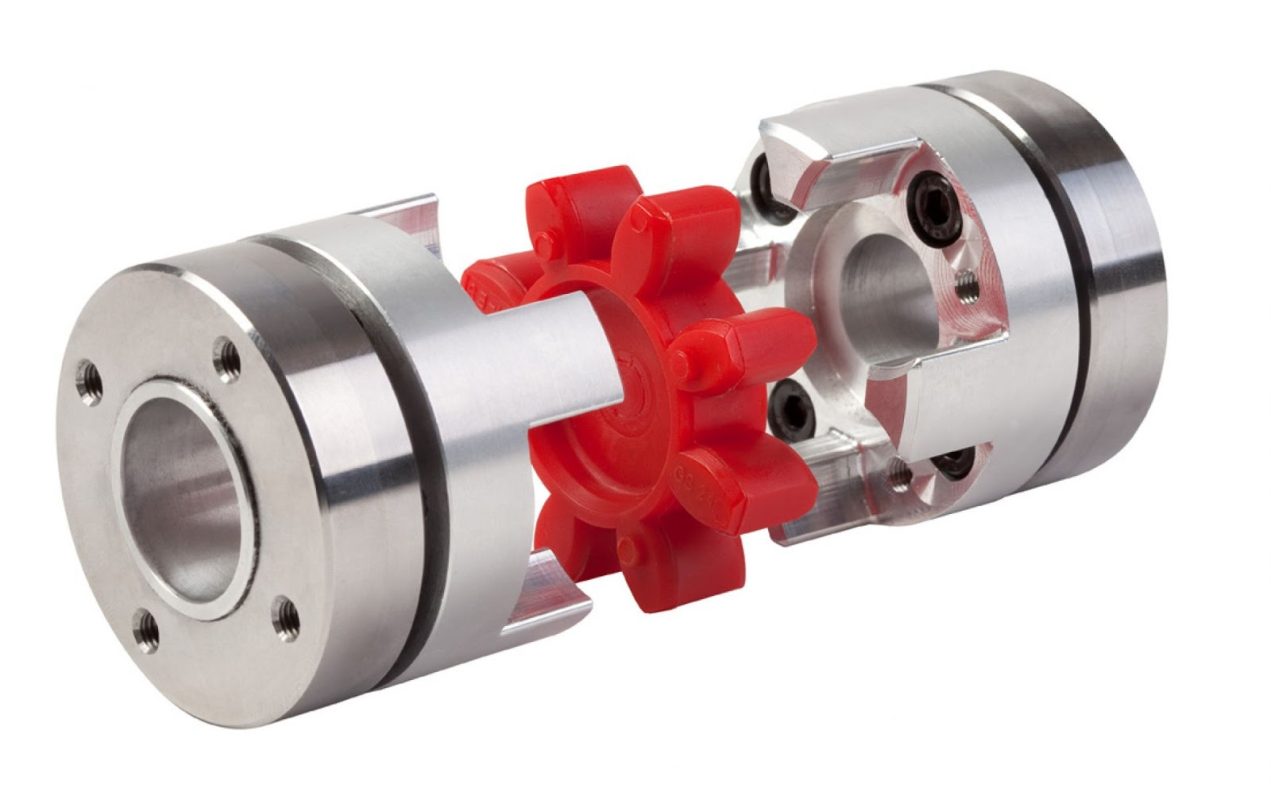

Couplings

Couplings are components that are used to connect two shafts to each other so that they can continuously or intermittently transmit power from one shaft to another. These components not only transmit torque, but in many cases, they also have the ability to compensate for deviations or misalignment between the two shafts. Their two main types are rigid and flexible couplings, which are selected depending on the installation conditions and the type of movement required.

Bearings

Bearings play a key role in reducing friction between moving surfaces and ensuring smooth and silent movement in mechanical equipment. These components are usually installed at the connection point of the shafts to the body of the device to reduce friction force and facilitate rotational movement. Their two most widely used types include ball bearings for high speeds and roller bearings for heavier loads.

Domestically produced or imported industrial power transmission components?

Industrial power transmission components are available in the Iranian market both domestically produced and imported. In recent years, many domestic manufacturers have been able to launch products such as gearboxes, bearings, couplings and industrial clutches with acceptable quality. These components have been able to cover the needs of many industries such as steel, cement, petrochemical and food. Domestic production has become a cost-effective option in many industrial projects due to lower costs, faster access, and easier technical support.

However, in some specific cases, industries still turn to imported components, especially when more advanced technologies, higher precision, or general They have more useful life. Some power transmission parts in the industry that are imported from European or Asian countries are used especially in precision projects or high-capacity production lines.

Depreciation rate of industrial power transmission parts

Industrial power transmission parts naturally wear out over time and due to continuous work. This wear can occur for various reasons such as high load, high speed, improper lubrication or adverse environmental conditions such as humidity, dust and high temperature. The type and amount of wear varies depending on the type of part, quality of construction, installation method and use. For example, bearings will be damaged much faster if they are insufficiently or incorrectly lubricated, while gearboxes will eventually corrode or lose their accuracy under heavy load conditions.

For this reason, regular maintenance and periodic inspections are very important to increase the useful life of this equipment. If this issue is not addressed, not only will repair and replacement costs increase, but there is also a risk of production line downtime, which can cause significant losses to the business.

Important points for installing and maintaining industrial power transmission components

Industrial power transmission components play a vital role in the proper functioning of mechanical systems, and observing the principles of their installation and maintenance can prevent many failures and additional costs.

Accurate installation and proper alignment

In the installation process, accuracy in the alignment of moving components is vital. Any deviation in the installation of shafts or misalignment between connected components can cause severe vibrations and ultimately internal damage to the system. Improper installation is one of the most common causes of premature failure in power transmission systems.

Accurate selection of components according to working conditions

To use each of the industrial power transmission components correctly, its selection must be appropriate to the load, speed, and working environment conditions. A component designed for a light industry may suffer rapid damage in a heavy industrial environment. Therefore, it is very important to pay attention to the mechanical capacity and technical specifications when purchasing or designing a system.

Proper lubrication and oil level control

Proper lubrication plays an important role in reducing friction and preventing overheating of components. Using high-quality oil or grease that is selected according to the type of component and working conditions is one of the foundations of proper maintenance. Each component has a specific type of lubricant required, which is specified by the manufacturer.

Periodic inspections and preventive maintenance

One of the effective solutions in preventing sudden failures is to conduct regular inspections. Visually inspecting the condition of components, listening for abnormal operating sounds, controlling vibrations, and even testing the temperature of sensitive points can provide useful information about the health of the system.

Preventing overloading

One of the most important causes of failure in industrial power transmission components is applying excessive loads or sudden shocks to the system. If a part is designed to withstand a certain load, applying a higher load can seriously damage its internal structure.

Use of original and standard spare parts

When replacing damaged or worn parts, it is very important to choose spare parts with a reputable brand and standard technical specifications. The use of non-original parts may look similar to the original model, but they are at a lower level in terms of performance and resistance.

Safety tips for using industrial power transmission parts

Safety tips for using industrial power transmission parts are among the issues that are very important in protecting the lives of employees, preventing damage to devices and improving the performance of industrial systems.

Use of personal safety equipment

To protect workers when coming into contact with moving or high-powered parts, it is necessary to wear standard work clothes, durable gloves, safety glasses and non-slip shoes. This protective equipment significantly reduces the risk of injury. If hoses or pipes containing pressurized fluids or chemicals are used, the use of insulating and waterproof covers is recommended. Failure to use protective equipment can lead to irreparable damage in industrial environments.

Compliance with safety standards in installation and maintenance

All installation, maintenance and repair processes of industrial power transmission components must be carried out in accordance with valid international standards or the manufacturer’s technical instructions. The use of non-standard tools or incorrect installation can not only cause equipment failure, but also endanger the safety of employees. Accurate installation, secure screwing, alignment of components and ensuring the correctness of mechanical and electrical connections are among the measures that must be observed.

Installation of warning signs

In areas where there is a risk of contact with moving parts, electric shock or fluid leakage, the installation of clear and visible warning signs is a necessity. These signs should include information such as the type of hazard, preventive measures and emergency response instructions. Proper marking contributes greatly to worker awareness and accident prevention and is part of the safety culture of the industrial environment.

Cooperation with safety officials

The presence of safety experts and continuous cooperation with them in industrial environments plays an important role in identifying weaknesses and correcting processes. Safety officials can reduce the likelihood of risks arising from improper operation of industrial power transmission components by conducting periodic monitoring, training employees, and reviewing work methods. The use of risk analysis reports and reviewing past incidents can also be effective in future decision-making.

Providing adequate ventilation

In environments where dust, oil vapor, smoke, or hazardous gases from equipment operation exist D. The ventilation system plays a vital role in maintaining the health of employees. Proper ventilation allows the concentration of pollutants to reach the permissible limit and prevents the risk of explosion or poisoning. In addition to natural ventilation, the use of suction and air purification fans can double the safety of the environment.

Providing adequate lighting in the workplace

Working in dimly lit or dark areas increases the likelihood of mistakes, collisions with parts, or improper installation and maintenance operations. Therefore, the use of standard lighting around machinery and workstations is essential. Proper lighting not only increases work safety, but also improves personnel productivity. The light should be without severe shadows or glare and should be checked and adjusted periodically.

Buying and selling industrial power transmission parts

Buying and selling industrial power transmission parts is one of the vital stages in the supply chain of various industries, which requires high accuracy, sufficient understanding of technical needs, and interaction with reliable suppliers. These parts include a set of mechanical components such as gearboxes, couplings, chains, bearings, pulleys and belts that are responsible for transmitting mechanical energy in industrial systems.

Incorrect selection or purchase of a low-quality part can cause sudden stoppage of production lines and increase maintenance costs, so it is of particular importance to know the technical specifications, working capacity, manufacturer’s brand and compatibility with the existing system.

Price of industrial power transmission parts

The purchase and sale of industrial power transmission parts is affected by several factors that shape the price of these parts. The final cost of each part depends on parameters such as the quality of the raw materials used, manufacturing technology, manufacturer’s brand and its level of technical complexity. In addition, the difference between domestically produced parts and imported samples also affects the price; imported parts usually have a higher price due to transportation costs, customs tariffs and more advanced technology. Market conditions, supply and demand, and exchange rate fluctuations are also other important factors in determining the price of these products.