Industrial electrical equipment includes a wide range of electrical and electronic components and devices that are effective for operating or protecting industrial electrical devices. Buying and selling industrial electrical equipment includes a wide variety of options, each of which has specific applications and unique capabilities. Since factors such as voltage, power, resistance, and safety are very important in industrial electricity, these important issues should also be considered when purchasing industrial electrical equipment and components. Given the widespread and important use of this type of equipment in various industries, in the following article we will fully examine the most widely used types of equipment used in industrial electricity, their applications, and introduce the top domestic and foreign brands that produce this type of equipment.

What is industrial electricity?

Industrial electricity is actually related to the control and distribution of electricity in various industrial processes. Meanwhile, the use of industrial electricity is not limited to manufacturing industries; we also see its widespread use in various administrative, commercial, construction, and hospital sectors. Therefore, it can be said that industrial electrical equipment is very popular with large consumers. In general, industrial electricity is one of the main sub-branches of the distribution and consumption stage, which includes a variety of techniques, including:

• Electrical circuit design

• Mapping

• Monitoring

• Fundamental concepts such as electrical symbols

• Mathematical laws and relationships

• Investigation of electrical machines

• Transformers

• Power supplies

• Generators

Application of industrial electricity

Before examining the types of industrial electrical equipment, it is better to take a look at the different and key applications of industrial electricity. In all limited to extensive industrial environments, industrial electrical equipment and components are needed in order to control various processes. In other words, in industries such as refineries, workshops and manufacturing plants, hospitals, office and commercial buildings, we witness the effective and vital presence of industrial electricity and its equipment to control and protect processes related to electricity flow. Some of the applications of industrial electricity are as follows:

• Contactors are used to start motors.

• Various types of relays are needed to control, disconnect or connect actuators.

• Miniature switches should be used to protect components and devices against overcurrent or electrical overload.

• Switches are needed to disconnect, connect and control circuits.

• And…

All types of industrial electrical equipment

In the market for buying and selling industrial electrical equipment, we are witnessing an increasing acceptance by various industries in order to meet their vital needs. The growth of industries, the increase in various production activities and the creation of new and large industrial towns have doubled the importance of access to various types of industrial electrical equipment and components. It is true that to introduce the types of industrial electrical equipment, we must refer to a long list of components and devices; But some of the most widely used and important industrial electrical equipment and components include the following:

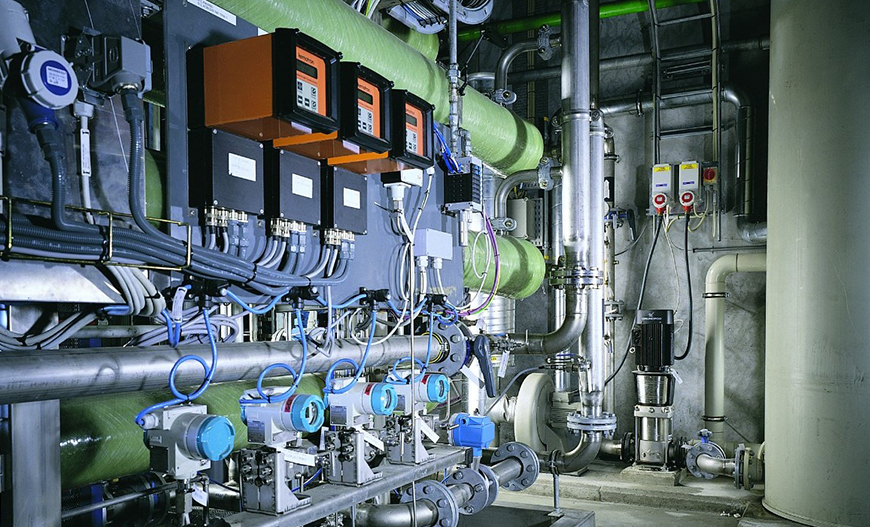

Power supply and distribution

A power supply is a type of electrical device whose main function is to provide the electrical power required by the load. There are types of power supply and distribution that can be embedded in various devices or placed separately inside circuits. Power supplies receive electrical energy by having an input connection and have one or more outputs to transfer electricity to the load. The input and output of the power supply often include different wired connections; while some other types of power supply and distribution without wired connections transfer inductive (wireless) energy to power the loads. The types of power supply are distinguished by considering two important factors of output current and how the voltage is regulated:

Regulated power supply

Unregulated power supply

Adjustable power supply

Isolated power supply

Contactor

Another of the most widely used industrial electrical equipment is the contactor, which is a type of electromagnetic switch. The contactor is actually the most important component of the electrical control circuit, which can be seen in every corner of the electrical industry. Using the contactor, remote control is possible and at the same time, it ensures the safety of the circuit. This functional part has a longer mechanical life than other switches and is excellent in preventing equipment from not working after power is cut off and reconnected. The contactor is very economical and is available in two general types: single-phase and three-phase.

Inverter

In the market for buying and selling industrial electrical equipment, we are faced with another functional equipment called inverters. These equipment are a type of electrical device and are responsible for controlling the speed of important equipment called three-phase electric motors. The inverter first converts the AC input power into DC power, and with the help of switching, it converts it into AC power with the required voltage and frequency. Depending on the type of operation of inverters, they are also called variable frequency and motor speed control.

Soft starter

Soft starter is another industrial electrical equipment that in some cases works similarly to an inverter. In this way, a soft starter is able to perform soft start of an electric motor like an inverter; but it does not have the ability to change the control and regulation of the motor speed. A soft starter can only control the current of AC motors and increase its current. Using a soft starter plays a key and vital role in protecting and safety of the electric motor against environmental stresses and ultimately increasing its service life.

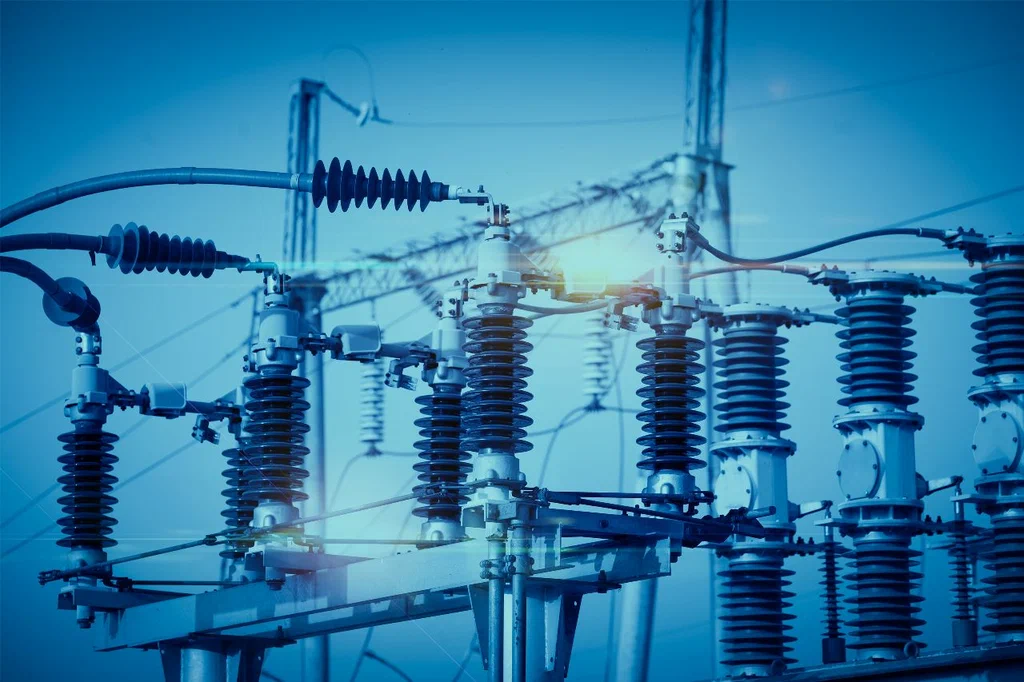

Power transmission and transformer

In the purchase and sale of industrial electrical equipment, one cannot The importance of transformer use in various industries has been overlooked. Transformers are in the category of equipment that are responsible for transmitting power and electrical energy. This device is often used to reduce or increase the supply voltage level between circuits, without changing its frequency range. The way transformers work is based on mutual induction and electromagnetic induction; for this reason, they are produced in two general types: step-up and step-down. This practical device is widely used in power generation networks, electrical energy consumption, distribution and electrical transmission sectors. The important features of the two main types of transformers are as follows:

1- Step-up transformer:

• Its main use is between the network and the generator.

• Its secondary output voltage is higher than the input voltage.

2- Step-down transformer:

• In order to convert power sources, it is responsible for converting high voltage input to low voltage output.

Indicators

Indicators are another industrial electrical equipment that is used as a signal light and to determine the status of the circuit. In order to know the exact status of the electrical system, different colors have been defined so that the device operator can easily and quickly find out the status of the device by observing it. The main components of all indicators include the following four important parts:

• A colored cover made of plastic and designed to allow light to pass through.

• A light source that often includes a lamp or LED.

• The body of the signal light

• The connector, which is actually the place where the power is connected to the signal light.

Indicators are used in various industries to help you see the operation of the device, the state of connection or disconnection of power, the method of switching off the device or system, and also to detect errors and problems. The colors of the signal light give you this information:

• Red; warning

• Yellow; warning of the need for caution

• Green; system readiness

• White; normal and problem-free conditions

• Blue; Diverse and definable applications such as door opening

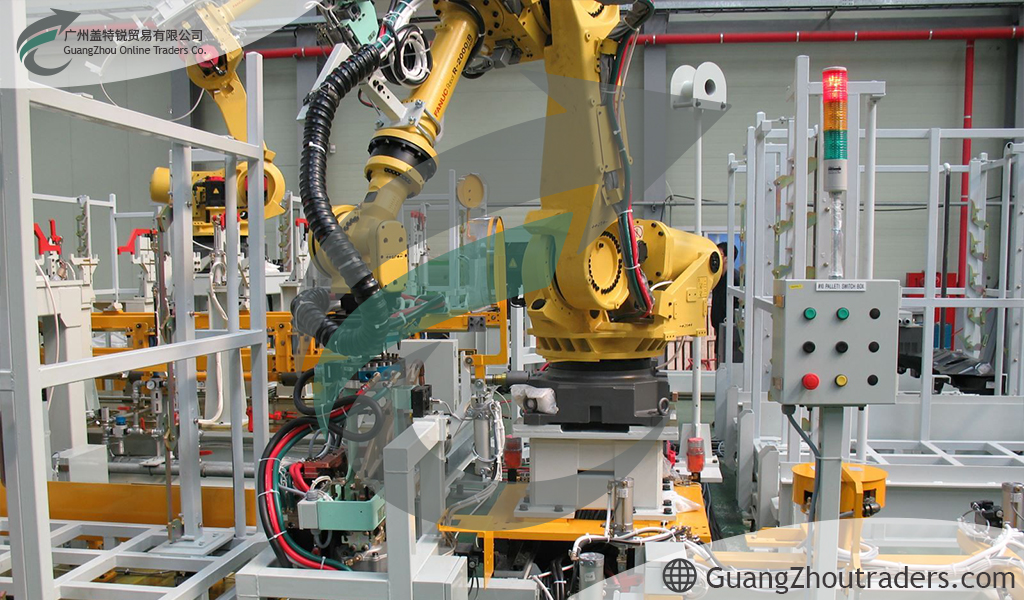

Electric machine

One of the most sought-after products in the industrial electrical equipment market is called an electric machine, which is used to change the voltage level of alternating currents to other voltage levels. An electric machine is actually a practical and important interface between electrical systems and mechanical systems. The way this connection is established in all electrical machines is based on the electromagnetic field. The widespread use of electric machines in various industries is such that their presence can be seen in many electrical and electrical devices around us. This is while this important equipment is used in industries and factories as the driving force of many tools and electric motors. In introducing the types of electric machines, the following two general categories can be mentioned:

• Types of electric machines according to the type of electric current:

1- Electric machines with direct current (DC)

2- Electric machines with alternating current (AC)

• Types of electric machines according to the type of energy conversion:

1- Electric generators with the ability to convert mechanical energy into electrical energy

2- Electric motors with the ability to convert electrical energy into mechanical energy

It should be noted that electric machines are among those industrial electrical equipment that are effective for nonlinear energy conversion; in other words, changes in input voltage are not always observed with the same ratio at the output of these equipment. It is interesting to know that the energy conversion process in electric machines is carried out reversible; meaning that, according to some practical instructions and considerations, it is possible to use them in the form of an electric motor (converting electrical energy to mechanical) or a generator (converting mechanical energy to electrical).

PLC

PLC is in the category of industrial electrical equipment control systems, which are also called industrial computers. This system is responsible for the complete control of all devices available in the network. In other words, each PLC performs the desired controls by defining custom programs for it. The presence of a central processing unit in each PLC leads to the identification of the tasks of this system and how to execute them correctly.

Wires and cables

Another of the most widely used equipment that is receiving significant attention in the industrial electrical equipment buying and selling market is called wires and cables. These equipment are actually conductors of electric current that help transfer electrical energy. Cables perform their functions by having one or more conductors and are insulated from the environment and from each other. All cables are known for their key characteristics and properties, including resistive, inductive and capacitive properties. Power transmission, energy transfer, and the protective role in returning fault current are considered to be the main characteristics of cables. Meanwhile, wires are also practical industrial electrical equipment that consists of only two layers of conductor and insulation. Wires are widely used to connect various internal components of electrical panels.

Types of insulation

Insulations help significantly protect and increase the safety and stability of cables. Depending on the type of cable and how they are used, various insulations are also produced, such as:

1- XLPE insulation:

• Excellent resistance to moisture, heat and chemicals

• Ability to withstand very high temperatures

• Ability to withstand electrical stresses

• Suitable for harsh environmental conditions

• Has a higher operating temperature than PVC cable

2- PVC insulation:

• Practical and common cable protection

• No chemical properties

• Waterproof

• Suitable for very low or very high temperatures

• Low permeability

• Good performance in various environmental conditions

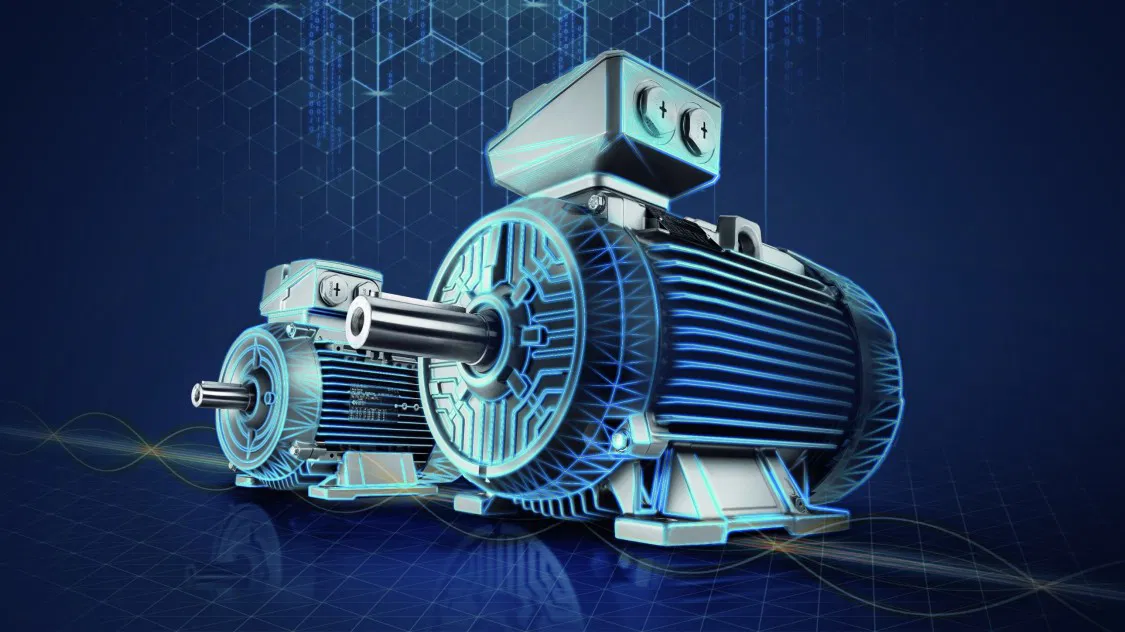

Generators and electric motors

In a diverse and countless list Types of industrial electrical equipment, it is time to introduce the generator or electric motor. A generator is actually a device that prevents interruption of work operations or disruption of daily industrial activities by producing electricity and power. To choose the most suitable electric generator in the market for buying and selling industrial electrical equipment, accurate calculations and a fundamental needs assessment must first be made; only then can you benefit from the highest and best efficiency of this device for your industry. The different types of generators and electric motors in terms of fuel consumption are as follows:

• Diesel generator

• Gas generator

• Dual-fuel generator

In addition to the aforementioned types of electric motors, this equipment can also be classified into two general models in terms of structure: without a canopy and with a canopy.

Personal and industrial protective equipment

Industrial protective equipment includes a wide range of electronic equipment, the main task of all of which is to protect electrical systems and devices. This type of industrial electrical equipment protects electrical systems from hazards and damage such as improper connections, breakage, low voltage, power fluctuations, etc. The operation of industrial electrical protection equipment is related to fault detection and then rapid power outage; in this way, we witness increased safety, reduced damage to equipment, and health risks for personnel and users. Industrial electrical protection equipment operates in a way that makes its presence necessary and essential for all industrial and non-industrial environments. Some of the most important industrial and personal protection equipment are:

Fuse

The simplest and most widely used industrial protection equipment is called a fuse. This component prevents overcurrent by being placed in series with the circuit. The simple structure of the fuse includes terminals, a fusible wire, and a body. If excess current passes through the circuits, the heat generated by it melts the fuse wire and ultimately breaks the circuit. Types of fuses as the main industrial electrical protection equipment include:

• Cartridge fuse

• Glass fuse

• Card fuse

• Cylindrical fuse

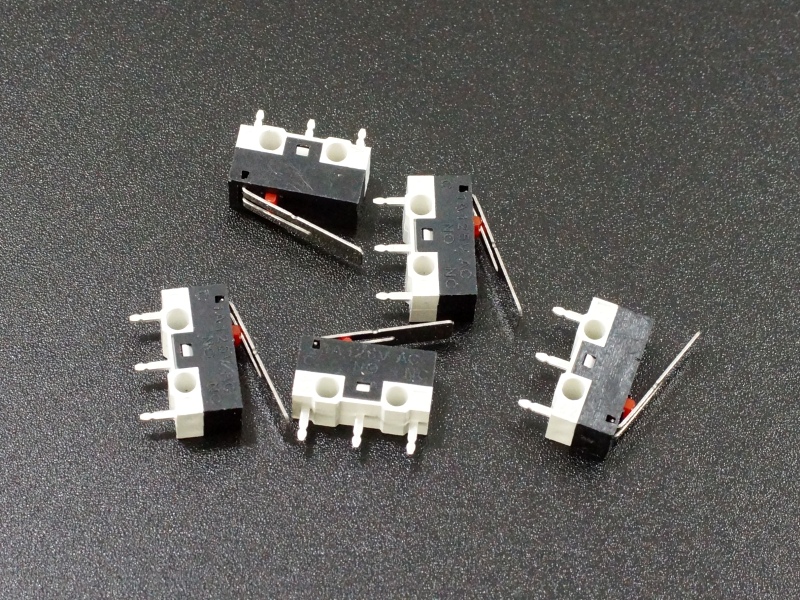

Miniature switch

Another industrial electrical equipment that is included in the category of protective equipment is the miniature switch. This electrical switch has automatic operation and is designed to protect electrical devices against overload or overcurrent. If excess current (exceeds the allowable limit) is generated in the circuit, the miniature switch is able to cut off the electrical connection and turn off the circuit altogether. This component is highly sensitive to high current and at the same time shows extremely fast performance.

Bimetal

In the market for buying and selling industrial electrical equipment, bimetal is very popular with the aim of protecting electrical equipment and devices against overcurrent. This component has two metal blades that are not the same. These two blades are connected to each other on one side; For this reason, when the heat of two metals is received by a metal with a low heat capacity, it takes on a curved appearance. Bimetal has an extraordinary ability to reduce motor speed overcurrent.

Thermal switch

Another industrial electrical protection equipment is the thermal switch, which protects electrical devices and equipment by being sensitive to overcurrent. In some types of thermal switches, we also see the sensitivity of this component to load imbalance and phase failure; in this way, they provide a more complete type of protection capabilities. This product is often used to protect electric motors, which is also available in a wide variety of types.

Load control relay

The load control relay is known for important tasks such as sampling the current and its complete monitoring. High operating accuracy and long service life are the main features of the load control relay. This industrial electrical protection component is not directly placed in the power circuit and is only used to determine the allowable current and overload time. If the current exceeds the defined values at the specified time, a contact is provided by the load control relay that you can use to protect the control circuit. In general, the load control relay is able to detect load loss and overload well.

Phase Control Relay

In introducing industrial electrical equipment that plays a protective role, it is the turn of the phase control relay. This functional component, also called a monitoring relay, is used to control load loss or overload, phase asymmetry, and phase sequence in all three-phase electrical systems. The phase control relay also performs the task of load control by having two blades; in such a way that when the component is triggered by overcurrent, the two blades of the phase control relay change position and return to their original position after the error is confirmed. It should be noted that this component is not designed to correct and manage errors; It only denies the system permission to start the circuit. The different types of phase control relays are as follows:

• Three-phase

• Single-phase

• Analog

• Digital

In the market for buying and selling industrial electrical equipment, we witness the presence of devices and parts, some of which are produced by domestic companies and others by imported brands. Many reputable companies in Iran are active in the field of industrial electrical equipment, the names of some of the most famous of which are as follows:

1- Elektroresa Company:

This company is one of the most famous manufacturers of industrial electrical equipment and systems that produces and supplies diverse and high-quality products at a reasonable price. The use of high-quality raw materials and reliance on modern knowledge by the large Elektroresa group has led to the production of high-quality and durable equipment.

The long service life has led to some of Elektroresa’s industrial electrical products include:

• All models of heating elements

• Types of thermocouples

• Analog thermostats

• Digital thermostats

• Temperature transmitters

• Types of contactors

• Relays

• Electrical panels

• Signal lights

• And …

Top global brands of industrial electrical equipment

As mentioned, in the market for buying and selling industrial electrical equipment, some products are seen that are produced by global brands. Importing modern and up-to-date industrial electrical equipment is essential and inevitable in order to meet the diverse needs of domestic industries. Among them, there are some leading global brands in the field of industrial electrical equipment production, whose names are as follows:

• Siemens:

The largest industrial electrical equipment and parts production company that designs and manufactures various products such as automation equipment, industrial electrical equipment, and control systems.

• Schneider Electric:

This company is also one of the leading brands in the field of industrial electrical products, which, in addition to manufacturing quality, focuses heavily on smartization, reducing energy consumption, and optimizing various industrial processes.

• ABB:

This international company is also one of the famous brands producing industrial electrical equipment in the world, and its products are used in many industries.

• Hitachi:

This large Japanese company is also active in the field of producing advanced industrial electrical equipment in the fields of automation, power generation, and energy management systems.

Buying and selling industrial electrical equipment

When buying and selling industrial electrical equipment, you are faced with a variety of devices and countless parts, which may make choosing the most appropriate equipment challenging. For this reason, you should first consider your needs and priorities and then prioritize purchasing from the most reputable suppliers. Buying industrial electrical equipment from reputable and professional sellers will lead you to a satisfactory and practical shopping experience. In the meantime, it is necessary and essential to examine some important and effective factors when choosing suppliers of industrial electrical equipment and parts, including:

• Reviewing production standards and manufacturing quality certificates

• Paying attention to product diversity

• Reviewing customization capabilities

• How to provide after-sales service

Price of industrial electrical equipment

There are many influential factors in determining the price of industrial electrical equipment that you should be familiar with in order to increase your skills in evaluating prices and comparing prices offered in the market. Factors affecting the pricing of industrial electrical equipment and components include:

• Type of equipment

• Build quality and safety

• Manufacturer’s brand

• Warranty type

• Exchange rate

• Production costs

• Material used in its manufacture

• And…