Converting Thermal and Kinetic Energy into Mechanical Power

Turbines are rotary mechanical devices that extract energy from a moving fluid—such as steam, gas, or water—and convert it into mechanical work. This work is typically used to drive compressors, pumps, generators, or mechanical loads across various industries including power generation, oil & gas, refining, petrochemicals, and renewables.

Turbines are categorized based on the working fluid and energy source:

-

Steam Turbines

Overview

Steam turbines convert the enthalpy of pressurized steam into rotary motion using sets of high-precision blades. They are a cornerstone in thermal power generation and process steam recovery systems.

Types:

- Condensing Steam Turbines

- Back-Pressure (Non-Condensing) Turbines

- Extraction-Condensing Turbines

- Reheat Turbines

Standards:

- API 611 – General Purpose Steam Turbines

- API 612 – Special Purpose Steam Turbines

- ASME PTC 6 – Steam Turbine Performance Test Code

Applications:

- Power plants (Rankine cycle)

- Mechanical drives (pumps, compressors)

- Heat recovery systems

- Cogeneration (CHP systems)

-

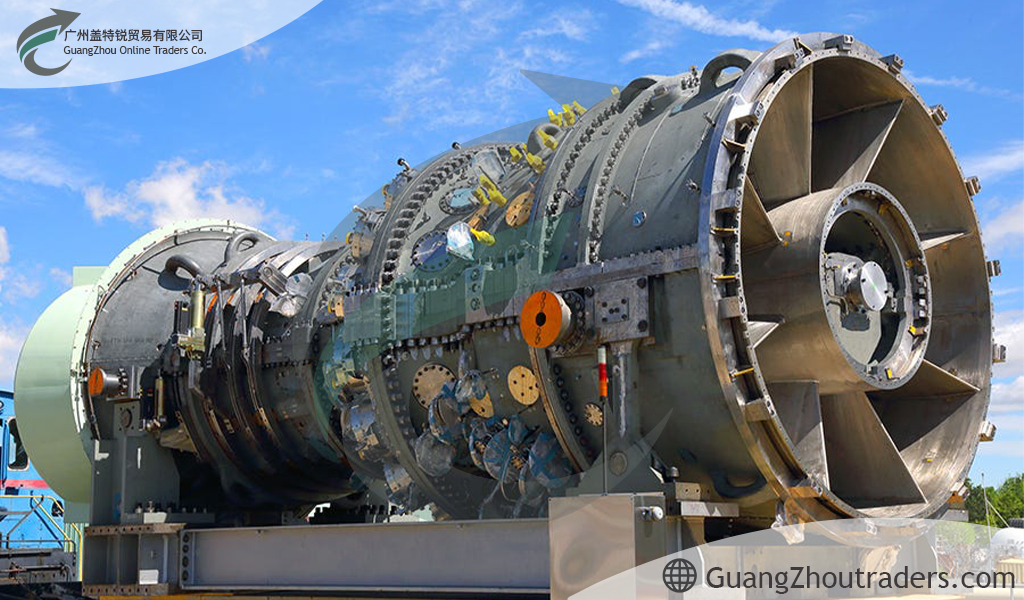

Gas Turbines

Overview:

Gas turbines operate on the Brayton cycle and burn fuel to generate high-velocity gas that drives the turbine blades. They are prized for their high power-to-weight ratio and rapid start capability.

Types:

- Industrial Gas Turbines

- Aero-Derivative Gas Turbines

- Open Cycle Gas Turbines (OCGT)

- Combined Cycle Gas Turbines (CCGT)

Standards:

- API 616 – Gas Turbines for the Petroleum, Chemical, and Gas Industry Services

- ISO 3977 – Gas Turbine Procurement and Design

- ASME PTC 22 – Gas Turbine Performance Testing

Applications:

- Combined cycle and peaking power plants

- Mechanical drives for compressors and pumps

- Offshore platforms

- LNG production facilities

- Hydraulic (Water) Turbines

Overview:

Hydraulic turbines use water pressure and kinetic energy to produce rotational power, most commonly for electricity generation.

Types:

- Impulse Turbines: Pelton wheel (high head, low flow)

- Reaction Turbines: Francis, Kaplan (medium to low head, high flow)

Standards:

- IEC 61116 – Guide for Hydraulic Turbines

- ISO 30606 – Performance acceptance tests

Applications:

- Hydropower plants

- Irrigation and flood control

- Pumped storage systems

Engineering Considerations:

- Thermodynamic efficiency (isentropic or cycle efficiency)

- Inlet pressure and temperature of working fluid

- Rotor dynamics and balancing

- Load-following capability

- Control systems (governor, speed control, load sharing)

- Vibration and acoustic limits (per ISO 7919, ISO 10816)

Optional Enhancements

- Combined Heat and Power (CHP) integration

- Exhaust heat recovery systems (HRSG)

- Remote monitoring and predictive maintenance modules