Enabling Efficient Fluid Transfer Across Critical Industries

Pumps are fundamental components of fluid handling systems, converting mechanical energy into hydraulic energy to move liquids across pipelines and process units. They are broadly categorized into Dynamic and Positive Displacement types, each designed for specific flow behaviors, pressures, and media characteristics.

1. Dynamic Pumps

These pumps impart velocity to the fluid, converting kinetic energy into pressure energy. They are ideal for high-flow, low-to-medium pressure applications.

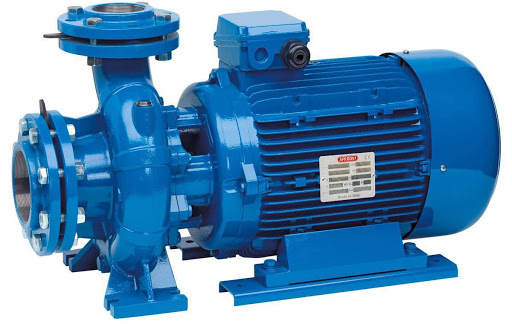

1.1 Centrifugal Pumps

Principle: Use a rotating impeller to add velocity and pressure to the fluid.

Types:

- End-Suction

- Multistage

- Vertical Inline

- Horizontal Split Case

- API Process Pumps

Standards:

- API 610 – Centrifugal Pumps for Petroleum, Petrochemical, and Natural Gas Industries

- ISO 5199 – Technical specifications for industrial process pumps

- Applications: Crude transfer, water injection, cooling water, chemical circulation

1.2 Special Dynamic Types

- Mixed Flow Pumps – Combine axial and radial flow for high volume, moderate head.

- Axial Flow Pumps – Suitable for very high flow, low head applications like flood control and cooling towers.

- Jet Pumps – Used in well applications, employ a nozzle-venturi effect.

2. Positive Displacement (PD) Pumps

PD pumps trap a fixed volume of fluid and force it through the discharge line. They are suitable for high-pressure, low-flow applications and are highly effective with viscous, shear-sensitive, or multiphase fluids.

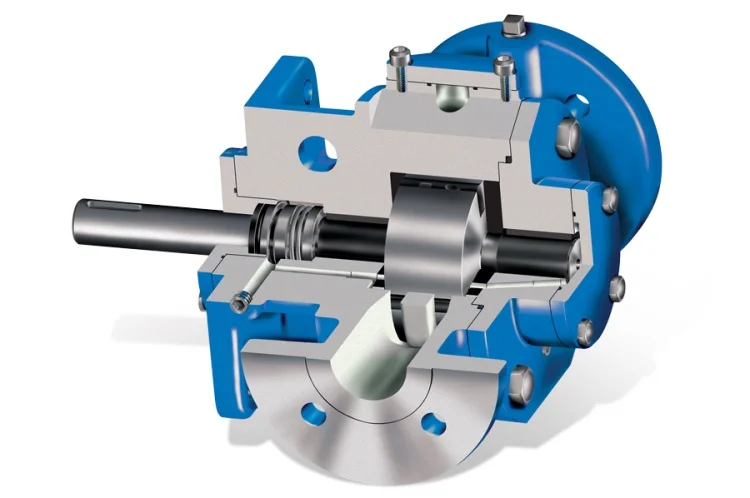

2.1 Rotary PD Pumps

Principle: Fluid is moved by rotating elements creating cavities that transport the fluid.

Types:

- Screw Pumps (Twin, Triple Screw)

- Gear Pumps (Internal, External)

- Vane Pumps

- Lobe Pumps

Standards:

- API 676 – Positive Displacement Pumps for Petroleum, Petrochemical, and Gas Industry Services

- ANSI/HI 3.1–3.5 – Rotary pump standards

- Applications: Lubricating oil transfer, fuel oil handling, asphalt and resin pumping

2.2 Reciprocating PD Pumps

Principle: Use pistons or diaphragms to displace fluid with each stroke.

Types:

- Piston Pumps

- Plunger Pumps

- Diaphragm Pumps

Standards:

- API 674 – Positive Displacement Reciprocating Pumps

- API 675 – Controlled Volume Metering Pumps

Applications: High-pressure injection, dosing chemicals, high-viscosity slurry handling

Selection Criteria

When specifying a pump, engineers should evaluate:

- Flow rate (m³/hr or GPM)

- Total dynamic head (TDH)

- Suction conditions (NPSH)

- Viscosity & temperature of the fluid

- Abrasive or corrosive nature of the media

- Availability of power and control systems