Buying and selling iron and steel has taken up a significant portion of the market for industries related to construction, tool production, machinery, and other products. In general, iron and steel are considered the main raw materials in various industries, which also have a wide range of applications; to the point that they are prominent in more than 90 percent of industrial applications. The existence of different types of iron and steel has been able to meet many diverse industrial needs. Since iron is among the most widely used industrial and construction raw materials, in the following article we will examine everything you need to know about this product and its applications.

Types of Iron and Steel

As mentioned, buying and selling iron and steel has taken up a large portion of the materials market due to its different types. Various shapes of iron and steel have been created to meet the different needs of consumers, and we will introduce some of the most widely used ones below:

Profile or can

A profile is actually a hollow metal section that is produced in various shapes and for various applications. The strong presence of profiles is especially noticeable in the construction industry; to the extent that a significant portion of profile customers include builders. The most common types of profiles include rectangular and square cross-sections, which are also known as cans in the market. It should be noted that two important factors, surface area and thickness, play an important role in determining the final price of the profile.

Iron beam

In examining the purchase and sale of iron and steel, there is another product called iron beam, which is known for its widespread use in the construction industry. The cross-section of the iron beam is in two shapes: H and I, both of which are responsible for bearing the load in various structures. The different and widely used types of beams, each of which offers unique applications, are as follows:

• IPE beam

• INP beam

• Wide-wing beam (or hash)

• Honeycomb beam

Rebar

Another type of iron and steel is rebar, which has a solid and circular cross-section. In the construction industry, various types of rebar are used for various parts of the structure, such as columns, foundations, and reinforced concrete. In terms of appearance, types of rebar can be divided into two main categories, including:

• Plain rebar: has a polished and smooth surface.

• Ribbed rebar: is known for its protrusions on its body.

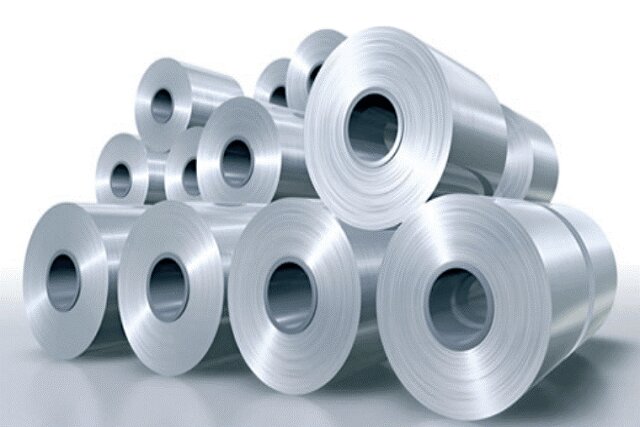

Sheet

In the purchase and sale of iron and steel, we are also faced with another best-selling product called sheet. Sheet types can be divided into four general categories, each of which is useful for certain construction needs, including:

• Extruded sheet

• Colored and ribbed aluminum sheet

• Cold sheet

• Hot sheet

The types of sheets mentioned can be used for specific and unique applications; for example, if the appearance of the structure is of great importance, you should prioritize the use of cold or oiled sheet. However, hot sheet must be used to strengthen the structure.

Angle and gutter

Among other types of iron and steel, angle and gutter should be mentioned. An angle is actually a product whose cross-section has two sides and a specific angle next to each other. You can prepare an angle in two forms: unequal wing and equal wing.

A gutter also functions as an open profile, whose appearance resembles the English letter U. You can also buy gutter products in different and diverse types according to your priorities, needs, and budget.

Pipe

In the purchase and sale of iron and steel, there is another product called pipe, which is known for its circular cross-section. This product is produced in two types: metallic and non-metallic, each of which has special and unique applications. The main use of pipes is related to the transfer of fluids. The metal type of pipe, which is usually produced from iron or copper, falls into two general categories: seamless and seamless.

Ingots

Ingots are also another steel product that can be seen in the market in three different types, including:

• Billets or ingots; with a cross-section of less than 15 centimeters

• Blooms or ingots; with a square cross-section of more than 15 centimeters

• Slabs or slabs; With a rectangular cross-section

As you can see, in classifying ingots into three main groups, attention has been paid to the factors of the shape of the cross-section and its dimensions.

Scrap

In examining the iron and steel buying and selling market, it is time for a product called scrap, which is actually iron scrap and steel surpluses. Since it is possible to recycle and reuse iron scrap, this product has also found widespread use in various industries.

Raw materials for iron and steel production

One of the most important things that receives a lot of attention in buying and selling iron and steel is the raw materials used in the production of iron and steel. Ore, which is actually a type of iron oxide, is the main raw material used in the production of iron and steel. Iron oxide is obtained from the combination of iron and oxygen, and the most important of them is hematite. The most abundant hematite is called limonite, which is also known by names such as magnetite, brownstone and taconite.

One of the reasons why this type of iron oxide ore is called magnetite is related to its magnetic properties and the highest iron content in it. Typically, iron and steelmaking furnaces require at least 50 percent iron ore to achieve the best degree of performance in ironmaking. After enrichment, the ore powder is combined with other required raw materials such as coal dust and also mixed binder.

Applications and Prices

Iron is widely used in many industries due to its high strength, excellent resistance, and reasonable price. The boom in buying and selling iron and steel in the construction of structures, the production of industrial machinery, the manufacture of automobiles, the hulls of large ships, transportation equipment, and … shows the high efficiency of this product. In determining the price of iron and raw steel, in addition to efficiency, great attention is also paid to its weight. Meanwhile, the price of this valuable and widely used metal will vary and differ depending on factors such as the type of iron, its thickness and dimensions, production standards, and the economic conditions prevailing in the market. It is interesting to know that the price of iron and raw steel may face significant changes on a daily basis and under the influence of fluctuations in the metal market.

How to grade the quality of iron and steel

One of the most important issues that affects the iron and steel buying and selling market is the quality of these products. All types of iron and steel sheets must go through three main stages for quality control, including:

1- Prevention stage; with the aim of reducing the number of errors that may occur when working with these products

2- Inspection stage; with the aim of inspecting and eliminating all defects

3- Tolerance stage; Aiming to keep the product quality within acceptable limits and taking into account the parameters related to quality control

In addition to the three main stages in controlling and grading the quality of iron and steel, there are also some test methods that are carried out to check and control the quality in terms of mechanical and physical properties of the product, such as:

• Hardness test to measure its hardness

• Tensile test to measure the product’s resistance and yielding to deformation, including breaking

• Visual inspection test to check for external defects such as warping, cracking, severe twisting, openness, etc.

• Hardness test to determine the distribution and depth of hardness of the product after cooling

• Metallurgical test to check the quality of iron and steel by measuring the details of the product sample with a microscope

• Impact test to measure the quality of iron and steel when hit

• Flexibility test to measure the variability of the product against various factors

• Abrasion test to measure the resistance of iron and steel against abrasion

• Compression test to determine the resistance of the product against factors such as pressure

• Corrosion test to measure the reactions of iron and steel against chemical processes

• Radiographic testing to check for existing gaps or incomplete weld joints

• And…

The best way to buy and sell iron and steel

To buy and sell iron and steel, it is better to enter this field with full knowledge. It is recommended to take these steps seriously in order to achieve the best method of buying and selling iron and steel:

• Determine your needs, especially in the field of the type of iron and steel, the intended application, the appropriate quantity and all its technical specifications.

• Before buying or selling these products, be sure to know the needs of the market and professional suppliers. In general, you should be aware of all aspects of the vast market for buying and selling iron and steel.

• Compare and check prices, especially among well-known and experienced suppliers.

• To buy iron and steel, be sure to go to a reliable and experienced supplier. Also, when buying, you should check all the standards and technical specifications of the product.

• Since many factors affect the fluctuation of the iron market, be sure to consider market conditions before buying or selling.

Factors affecting the price of iron and steel

One of the main and most effective factors in buying and selling iron and steel is price. Since you will encounter different prices when buying these products, it is better to be familiar with the most important factors affecting the price of iron and steel, including:

• Global oil prices; In such a way that with the increase in oil prices, we also see an increase in the price of iron and steel.

• Prices of raw and applied materials in the steel industry; The price of some raw materials such as coal and iron ore has a direct impact on determining the price of iron and steel.

• Transportation prices; The rate of transportation of raw materials to the factory and the final product to the market, especially for long distances, plays a significant role in changing the price of iron and steel.

• Exchange rate fluctuations; The increase in the exchange rate is accompanied by an increase in the cost of purchasing raw materials, energy supply and labor, which ultimately affects the price of iron and steel.

• Supply and demand; Supply and demand conditions are also other factors determining the price of iron and steel; so that with increasing demand, we also witness an increase in the price of iron and steel.

• Technical and physical specifications of the product; dimensions, thickness, quality, type of iron and steel, etc. are considered to be the most effective factors in determining its price.