Precision Power Transmission for High-Torque Industrial Applications

Gearboxes (or gear reducers) are mechanical devices used to transfer power between rotating shafts by modifying torque, speed, and direction of rotation. They are critical in industrial machinery, offering load matching between motors and driven equipment such as pumps, compressors, mixers, and conveyors.

Gearboxes enable energy-efficient and reliable transmission by leveraging gear trains and high-precision components designed to meet diverse mechanical loads, speeds, and environmental conditions.

1. Classification by Gear Type

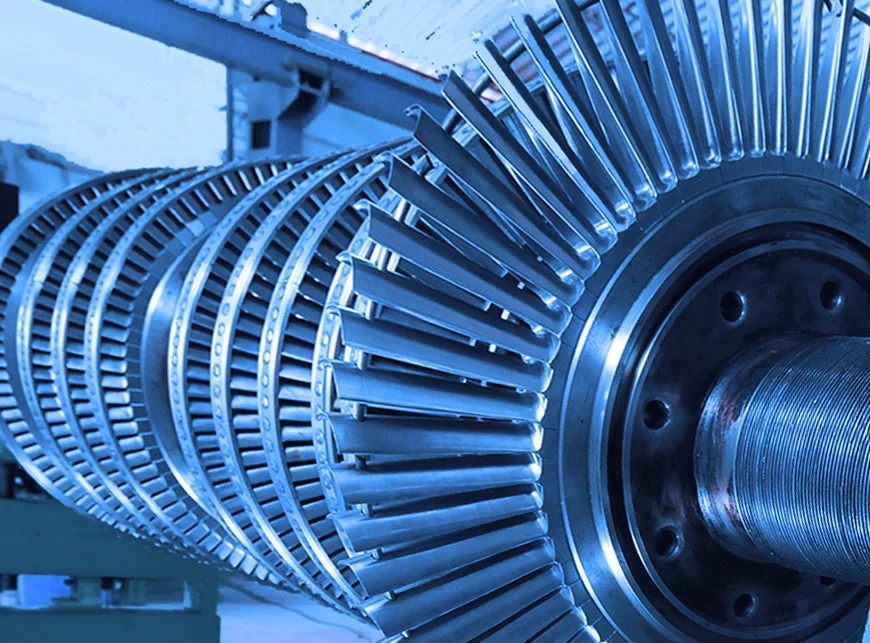

1.1 Steam Turbines

Features:

- High efficiency and load capacity

- Smooth and quiet operation due to angled teeth

Common Types:

Inline helical

Parallel shaft helical

Applications: Mixers, conveyors, blowers, cranes

1.2 Bevel Gearboxes

Features:

- Change shaft rotation angle (typically 90°)

- Spiral or straight bevel teeth

Common Configurations:

- Bevel-helical

- Right-angle drives

Applications: Agitators, right-angle pump drives, gear motors

1.3 Worm Gearboxes

Features:

- High gear reduction in compact form

- Self-locking in some configurations

Efficiency: Lower than helical/bevel but compact and cost-effective

Applications: Small conveyors, lifts, rotary tables

1.4 Planetary Gearboxes

Features:

- Coaxial shaft arrangement

- Very high torque density and compact size

Efficiency: High (up to 98%)

Applications: Wind turbines, industrial robots, compact drives

2. Industry Standards & Guidelines

- AGMA (American Gear Manufacturers Association):

- AGMA 6010 – Design of Industrial Gear Drives

- AGMA 6000 – Specifications for enclosed gear drives

- ISO 6336 – Calculation of load capacity of spur and helical gears

- DIN 3990 – Gear strength calculation

- API 613 – Special-Purpose Gear Units for Petroleum Applications

- API 677 – General-Purpose Gear Units

3. Selection Parameters

Engineers typically consider:

- Output torque (Nm)

- Speed ratio (input vs output RPM)

- Input power (kW or HP)

- Mounting position (horizontal, vertical, shaft orientation)

- Gear material (for corrosion, wear, or temperature resistance)

- Lubrication type (splash, forced oil, synthetic grease)

- Service factor based on load profile (shock, cyclic, continuous)

4. Common Applications

- Pump and compressor drives in oil & gas

- Wind turbine nacelle gearboxes

- Extruders and mixers in chemical and plastic plants

- Conveying systems in mining and cement

- Marine propulsion systems

- Crane hoists and lifting equipment

Optional Features

- Integrated backstops or torque limiters

- Vibration and temperature sensors

- Condition monitoring interfaces (IIoT ready)

- Cooling systems for high-load applications