CompressorsHigh-Performance Gas Compression for Industrial Processes

Compressors are mechanical devices designed to increase the pressure of gases by reducing their volume. Similar to pumps, compressors are classified into two broad categories based on their operating principles: Dynamic and Positive Displacement compressors. They are critical in industries such as oil & gas, petrochemicals, power generation, HVAC, and industrial refrigeration.

1. Dynamic Compressors

These compressors impart kinetic energy to the gas using rotating impellers or blades. The energy is then converted into pressure energy through diffusion.

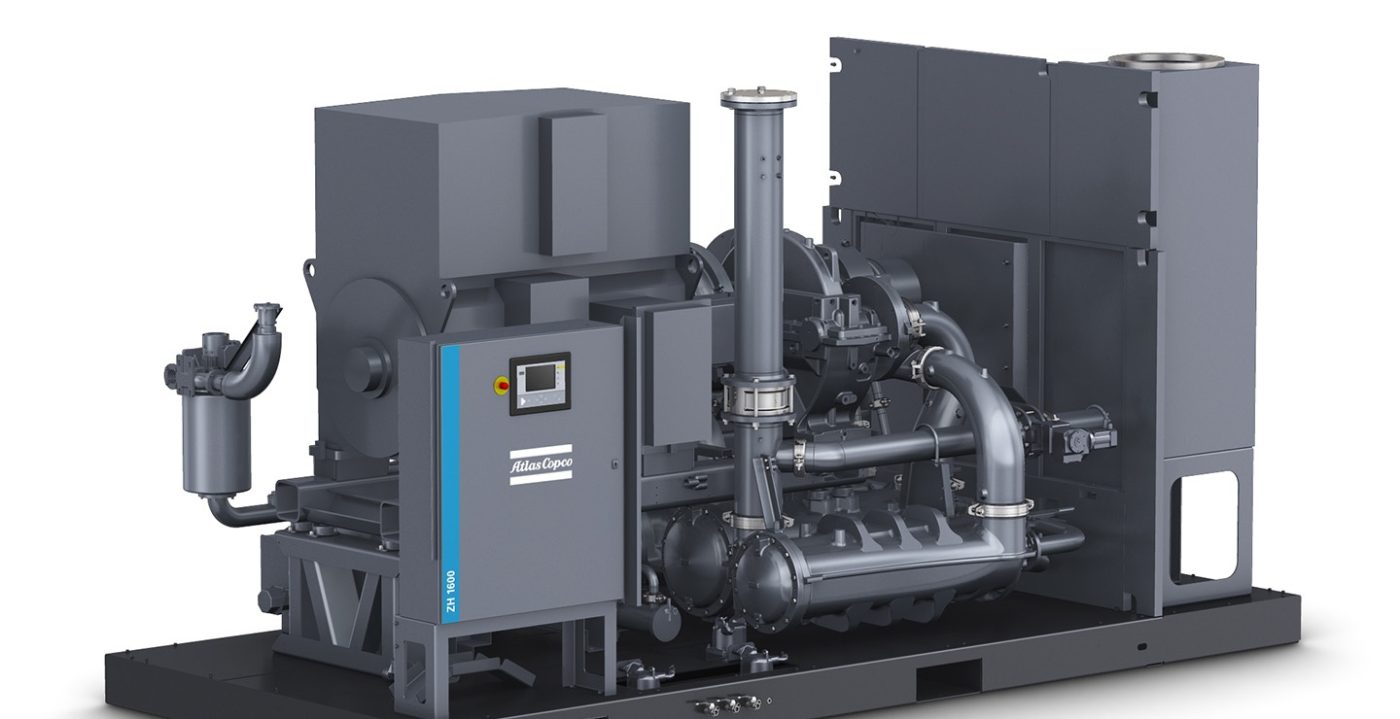

1.1 Centrifugal Compressors

- Principle: Gas enters the center of a rotating impeller and is accelerated outward through centrifugal force.

- Types:

- Single-Stage Centrifugal

- Multistage Centrifugal

- Integrally Geared Compressors

- Standards:

- API 617 – Axial and Centrifugal Compressors and Expander-Compressors

- ASME PTC 10 – Performance test code for compressors

- Applications: Refinery gas services, pipeline transportation, air separation, nitrogen compression

1.2 Axial Compressors

- Principle: Gas flows axially through rows of rotating and stationary blades.

- Characteristics:

- High flow, moderate pressure rise

- Compact design with high efficiency at design point

- Standards: Included in API 617

- Applications: Large-scale gas turbines, power plants, jet engines

2. Positive Displacement Compressors

These compressors trap a fixed volume of gas and mechanically reduce its volume to raise pressure. They are suitable for high-pressure, low-flow applications and are more tolerant of variable conditions.

2.1 Reciprocating Compressors

Principle: Use a piston moving in a cylinder to compress gas.

Types:

Single-Acting / Double-Acting

Single-Stage / Multistage

Lubricated / Non-Lubricated

Standards:

API 618 – Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services

ISO 13631 – General-purpose reciprocating compressors

Applications: CNG fueling, hydrogen compression, refinery processes, gas reinjection

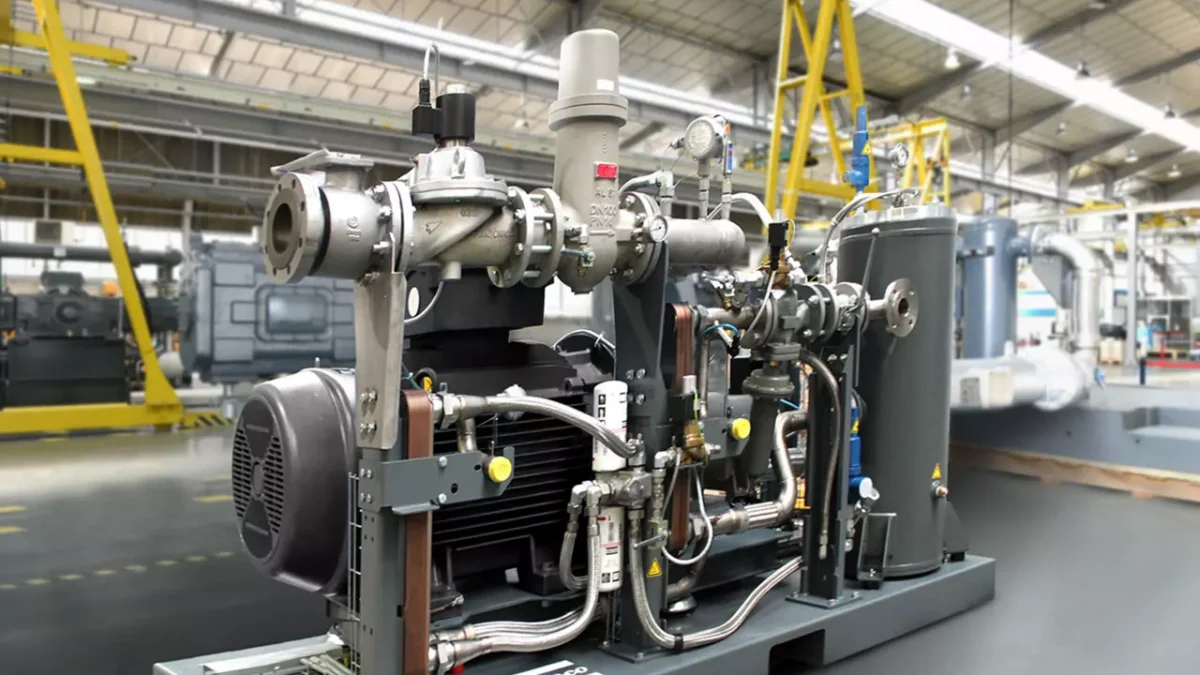

2.2 Rotary Compressors

- Principle: Use rotating elements to compress gas continuously in chambers.

- Types:

- Screw Compressors (Oil-injected, Oil-free)

- API 619 – Rotary-Type Positive Displacement Compressors for Petroleum, Petrochemical, and Natural Gas Industries

- Scroll Compressors – Quiet, efficient; used in HVAC

- Vane Compressors – Good for low-pressure air systems

- Lobe Compressors (Roots Blowers) – Pulsating flow, used for conveying air/gas

- Screw Compressors (Oil-injected, Oil-free)

- Applications: Instrument air systems, refrigeration, process gas delivery, pneumatic conveying

Selection Parameters

Engineers typically assess:

- Required flow rate (ACFM or Nm³/hr)

- Discharge pressure

- Gas composition and compressibility

- Inlet conditions (pressure, temperature, humidity)

- Cooling method (air-cooled, water-cooled, oil-cooled)

- Lubrication method (oil-free vs lubricated)

- Duty cycle (continuous, intermittent)