Automation and control equipment together are able to carry out various industrial and manufacturing processes by providing control programs without the need for human intervention. Buying and selling automation and control equipment includes devices that are used to control and implement production processes automatically. This equipment is especially suitable for those industries that involve difficult jobs and high-risk processes. Meanwhile, the use of automation equipment plays a significant role in improving the quality of work, reducing costs, and increasing production accuracy. To learn about the various applications of industrial automation and the classification of industrial control equipment, continue reading.

What is industrial automation and automation equipment?

The use of various control systems to manage industrial processes and monitor the operation of production machinery and equipment is called industrial automation. The use of automation and control equipment is effective in reducing human errors and ultimately increasing work accuracy and product quality. By relying on these equipment, systems and related technologies, you can take an effective step towards automating production processes and controlling industrial production lines. In other words, technological advances in the field of industrial automation have replaced manual controls with mechanical and automatic systems. It should be noted that industrial automation plays a vital role in setting up and managing automated production lines, to more complex applications such as robotics; to the extent that this path has led to the improvement and promotion of industrial functions. Industrial automation and its related equipment, in addition to creating a platform for efficient production, have also provided these important benefits:

- Reduced production time

- Reduced errors

- Reduced human interaction and presence in dangerous situations

- Improved working conditions

- Helping to create innovation in manufacturing industries

Application of Industrial Automation

Before introducing the main product classifications in the automation and control equipment buying and selling market, it is better to take a look at the main applications of industrial automation. In general, industrial automation includes the control of many devices around us, from complex industrial equipment and machinery; therefore, it can be said that control systems are associated with a wide and diverse range of applications. Some of the main applications of industrial control systems can be seen in the following industries:

1- Oil and gas industry:

- Control and monitoring of various processes, especially drilling and extraction stages

- Monitoring and control of various sections such as pumping stations and refining stations

- etc.

2- Food industry:

- Monitoring and control of food product production lines

- Automatic labeling and packaging stages

- Control of effective parameters in the production process such as pressure, humidity, temperature, etc.

3- Chemical industry:

- Complete control of various chemical production processes and monitoring their correct implementation

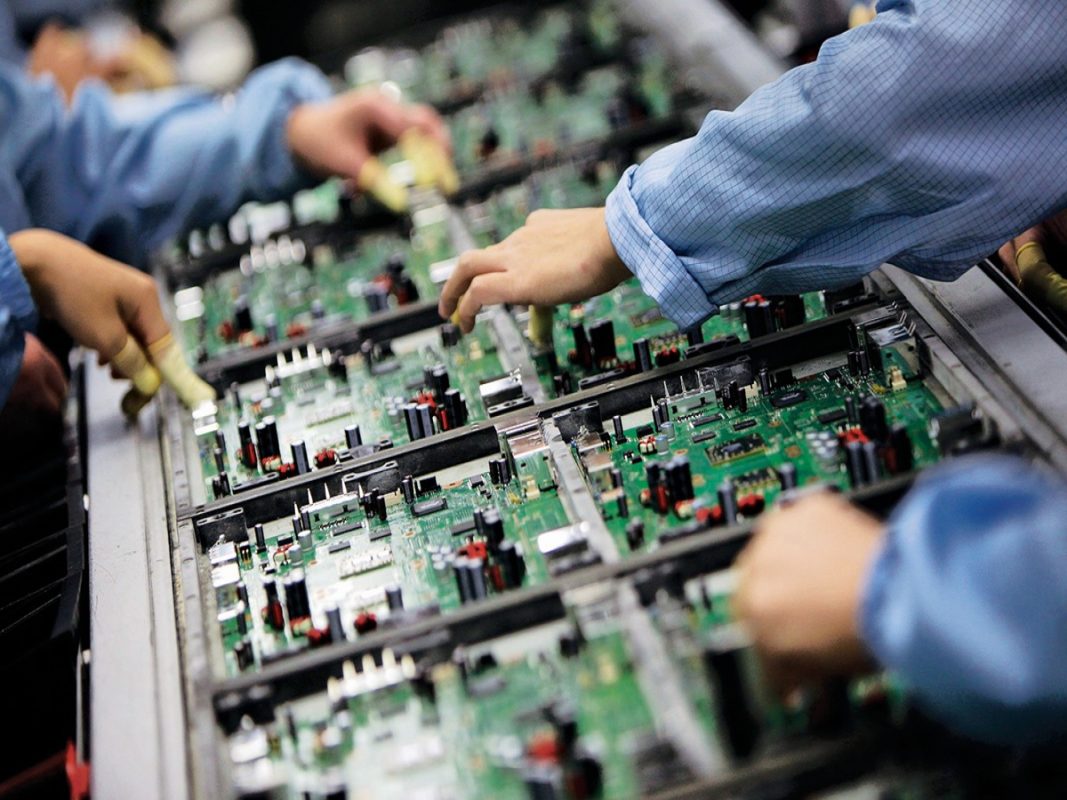

4- Electronics industry:

- Using industrial control robots to move equipment

- Using industrial control robots to connect various electronic components to each other

- Checking the quality of manufactured parts and conducting quality assessment tests with the help of automatic systems

5- Steel industries:

- Complete control of iron smelting and steel production processes

- Control of the casting stage

- Control of the shaping stage

6- Pharmaceutical industries:

- Automatic monitoring of drug production, packaging and labeling

7- General products manufacturing industries:

- Control of the production line of various products

Monitoring of workstations and production line stages

Innumerable cases should be mentioned to introduce the applications of industrial automation. Some other applications of industrial monitoring and control systems are as follows:

- Monitoring heating systems

- Performing switching operations

- Application in automatic bus doors

- Intelligent building control system

- And…

Classification of industrial automation and control equipment

As mentioned, in the market for buying and selling automation and control equipment, a wide range of systems and devices can be seen, each of which provides unique capabilities and specific efficiency to various industries. To classify the types of industrial control equipment, the following important, key and effective items can be mentioned:

Computer and processor

The brain of automation systems is formed by its central processing units. This unit, known by the abbreviation CPU, is responsible for processing all information received from the sensors of the automation system. Also, the central processor must execute customized and programmed instructions in order to control and manage the actuators. If the automation system requires high efficiency and performance, you should consider the processor speed and power in accordance with industrial needs. In the meantime, the computer is used to display a graphical view of various industrial processes that are under control and provide a variety of data, in addition to processing data and executing instructions.

In addition to the above, you can install some programs on the computer to fully monitor operator stations. In other words, remote control and on-site control in the control room are also possible with software installed on the computer. In this way, you can:

- View the operating status of devices and machinery in real time.

- Record and check the vital parameters defined for each industrial system.

- Be informed of various alarms that indicate errors and problems in the systems.

- See the location of failures and the time of their occurrence in all components of the industrial system, from the smallest to the largest.

- Make necessary corrections and changes during the execution of production processes.

The intelligentization of automation and control equipment has a great impact on increasing the quality control of production line processes. For this purpose, sensors are used instead of buttons to send a photo command to the cameras. The sensors send a signal to the camera in the event of weak pressure on the production line and the passage of products, and in this situation the camera is required to record data more quickly. The automatic system may not confirm the quality of the product by reviewing and processing the photos; in this situation, the central system sends a command to the jack to reject the product. Other applications of intelligent industrial automation equipment include the following:

• Support for programs that must control a large number of actuators and sensors.

• Support for applications that must perform a set of tasks in a customized and designed manner.

• Support for control systems that are set based on factors such as counting and time.

• They are also efficient for detecting humidity and temperature, energy consumption, and diagnosing problems and troubleshooting.

PLC

PLC is actually a type of computer device that is known for its features such as programmability, control, and logic. PLC is the most sought-after product in the purchase and sale of automation and control equipment; because it provides extraordinary efficiency to the industrial automation system. PLC is able to process and control a production line and its complete processes, the operation of machinery, and also a specific process in a fully automatic manner.

PLC processes information by receiving information from input devices or sensors connected to the equipment. Then, it produces and presents the output of the received information by considering defined and key parameters. This controller is able to record and maintain runtime data based on the type of input and output information.

Scanner

A scanner is another industrial control equipment that is used to read received information and convert it into archival data such as photos, documents, films, etc. The information obtained from scanners can be used to analyze data, identify problems, and evaluate processes at the appropriate time. There are different types of industrial automation scanners, and you should consider the needs related to process control when choosing their type and performance.

Switches

Another of the most widely used automation and control equipment is switches, which are effective in protecting and controlling important electrical circuits. Types of switches provide appropriate durability and reliability, taking into account priorities and the industrial environment. In the input section of industrial automation systems, two widely used types of switches are used, namely diagnostic switches and operational switches.

Encoder

An encoder is an important equipment in the automation system that allows the system to observe and track movements. Valuable information provided to the automation system controller is provided by converting motion into electrical signals. In this way, the system is able to understand the current situation and can make intelligent and effective decisions based on the data. Encoders, with high accuracy, correct analysis and fast response, play a very key role in controlling the motion and precise guidance of industrial devices.

Timers and Counters

In the automation and control equipment market, we witness the presence of various types of timers and counters, which are among the most important categories of automation equipment. Timers play an effective role in all operations related to the automation system, because they are able to automatically turn on and off the circuit at a specified and desired time. Some of the most widely used types of timers that are effective in industrial control systems are as follows:

• Delay timer for disconnection and connection

• Flasher

• Connection and disconnection

• And …

Another important component in the industrial automation system is known as a counter. This type of equipment is responsible for counting signals received from input devices or equipment with sensors. While all counters are also effective in controlling the output.

Connection relay

A relay is one of the most important automation and control equipment, which is actually a type of switch with electrical functions. Various types of relays are used to connect or disconnect electrical circuits related to automation systems. The presence of a connection relay is necessary and essential in all industrial automation systems to ensure the proper functioning of the IT section and the basic protection of equipment. Most relays use electromagnetic coils to perform their switching and other functions; among them, there are some types of relays whose operating principles are very different from those of conventional relays.

Temperature Controller

In introducing the types of classifications of automation and control equipment, it is time for temperature controller equipment. These equipment implement the necessary settings according to the user’s request by receiving a temperature sensor in the form of a signal. In other words, the task of the temperature controller in an industrial automation system is to monitor the received signals to maintain the default temperature. These equipment are especially effective in controlling heating devices. Temperature controller components are able to inform the user of the temperature by measuring the heat and temperature of the system components. In this way, it is possible to adjust the temperature and maintain its balance either manually by the operator or by equipping the automation system with automatic capabilities.